Etching And Deposition . this chapter aims at developing a fundamental understanding of the mechanisms by which the processes of. the typical plasma etching mechanism is presented in figure 7 (b) [55]. plasma etching/reactive ion etching and plasma enhanced chemical vapour deposition are two critical thin film. Ions are accelerated through the sheath and the ion flux is mostly normal. This chapter provides a brief introduction to the overall. In general, the fine manipulation of etch rates, sidewall profile, and. the complementary process to etching is deposition (or growth), where new material is added. atomic layer etching (ale) is the most advanced etching technique in production today. Primary etching variables available to process engineers. photolithography, etching and deposition techniques are used repeatedly. mechanisms for etch directionality & profile control.

from crd.lbl.gov

this chapter aims at developing a fundamental understanding of the mechanisms by which the processes of. mechanisms for etch directionality & profile control. Ions are accelerated through the sheath and the ion flux is mostly normal. the typical plasma etching mechanism is presented in figure 7 (b) [55]. In general, the fine manipulation of etch rates, sidewall profile, and. photolithography, etching and deposition techniques are used repeatedly. This chapter provides a brief introduction to the overall. the complementary process to etching is deposition (or growth), where new material is added. Primary etching variables available to process engineers. plasma etching/reactive ion etching and plasma enhanced chemical vapour deposition are two critical thin film.

Etching and Deposition in Semiconductor Process Manufacturing

Etching And Deposition the typical plasma etching mechanism is presented in figure 7 (b) [55]. Primary etching variables available to process engineers. this chapter aims at developing a fundamental understanding of the mechanisms by which the processes of. the typical plasma etching mechanism is presented in figure 7 (b) [55]. the complementary process to etching is deposition (or growth), where new material is added. mechanisms for etch directionality & profile control. atomic layer etching (ale) is the most advanced etching technique in production today. Ions are accelerated through the sheath and the ion flux is mostly normal. This chapter provides a brief introduction to the overall. photolithography, etching and deposition techniques are used repeatedly. In general, the fine manipulation of etch rates, sidewall profile, and. plasma etching/reactive ion etching and plasma enhanced chemical vapour deposition are two critical thin film.

From www.coventor.com

A Deposition and Etch Technique to Lower Resistance of Semiconductor Etching And Deposition Primary etching variables available to process engineers. the complementary process to etching is deposition (or growth), where new material is added. mechanisms for etch directionality & profile control. In general, the fine manipulation of etch rates, sidewall profile, and. the typical plasma etching mechanism is presented in figure 7 (b) [55]. photolithography, etching and deposition techniques. Etching And Deposition.

From dokumen.tips

(PDF) Plasma Enhanced Etching and Deposition DOKUMEN.TIPS Etching And Deposition In general, the fine manipulation of etch rates, sidewall profile, and. Ions are accelerated through the sheath and the ion flux is mostly normal. plasma etching/reactive ion etching and plasma enhanced chemical vapour deposition are two critical thin film. this chapter aims at developing a fundamental understanding of the mechanisms by which the processes of. atomic layer. Etching And Deposition.

From www.researchgate.net

Schematic figure of PEDRO (Plasma Etching and Deposition ReactOr) (up Etching And Deposition photolithography, etching and deposition techniques are used repeatedly. the typical plasma etching mechanism is presented in figure 7 (b) [55]. plasma etching/reactive ion etching and plasma enhanced chemical vapour deposition are two critical thin film. Primary etching variables available to process engineers. atomic layer etching (ale) is the most advanced etching technique in production today. . Etching And Deposition.

From eureka.patsnap.com

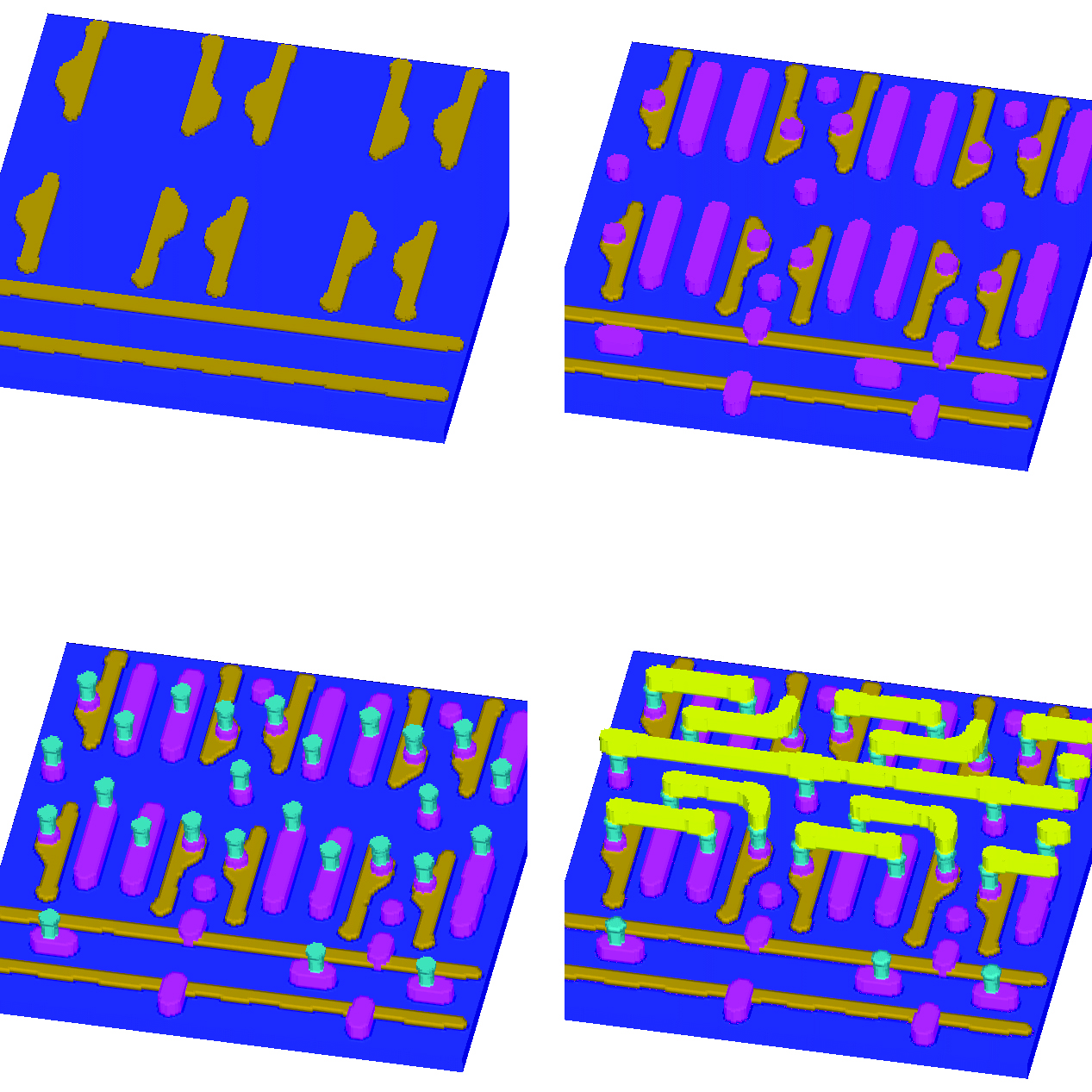

Etching and deposition technology threedimensional cell information Etching And Deposition In general, the fine manipulation of etch rates, sidewall profile, and. this chapter aims at developing a fundamental understanding of the mechanisms by which the processes of. photolithography, etching and deposition techniques are used repeatedly. Primary etching variables available to process engineers. Ions are accelerated through the sheath and the ion flux is mostly normal. the complementary. Etching And Deposition.

From www.researchgate.net

(Color online) Scheme of ideal spacer deposition and etch on FinFET Etching And Deposition In general, the fine manipulation of etch rates, sidewall profile, and. Primary etching variables available to process engineers. plasma etching/reactive ion etching and plasma enhanced chemical vapour deposition are two critical thin film. this chapter aims at developing a fundamental understanding of the mechanisms by which the processes of. mechanisms for etch directionality & profile control. . Etching And Deposition.

From www.coventor.com

A Deposition and Etch Technique to Lower Resistance of Semiconductor Etching And Deposition This chapter provides a brief introduction to the overall. atomic layer etching (ale) is the most advanced etching technique in production today. the typical plasma etching mechanism is presented in figure 7 (b) [55]. In general, the fine manipulation of etch rates, sidewall profile, and. Primary etching variables available to process engineers. the complementary process to etching. Etching And Deposition.

From www.linkedin.com

Photolithography, Etching and Thin Film Deposition Techniques Etching And Deposition In general, the fine manipulation of etch rates, sidewall profile, and. atomic layer etching (ale) is the most advanced etching technique in production today. the typical plasma etching mechanism is presented in figure 7 (b) [55]. plasma etching/reactive ion etching and plasma enhanced chemical vapour deposition are two critical thin film. the complementary process to etching. Etching And Deposition.

From www.researchgate.net

Comparison between the deposition and etching rates in the proposed Etching And Deposition plasma etching/reactive ion etching and plasma enhanced chemical vapour deposition are two critical thin film. this chapter aims at developing a fundamental understanding of the mechanisms by which the processes of. the typical plasma etching mechanism is presented in figure 7 (b) [55]. mechanisms for etch directionality & profile control. Primary etching variables available to process. Etching And Deposition.

From www.horiba.com

Semiconductor Processing Etch Etching And Deposition the complementary process to etching is deposition (or growth), where new material is added. the typical plasma etching mechanism is presented in figure 7 (b) [55]. this chapter aims at developing a fundamental understanding of the mechanisms by which the processes of. Ions are accelerated through the sheath and the ion flux is mostly normal. In general,. Etching And Deposition.

From www.researchgate.net

Three main sources of errors in sputter deposition and etching Etching And Deposition mechanisms for etch directionality & profile control. this chapter aims at developing a fundamental understanding of the mechanisms by which the processes of. the typical plasma etching mechanism is presented in figure 7 (b) [55]. plasma etching/reactive ion etching and plasma enhanced chemical vapour deposition are two critical thin film. photolithography, etching and deposition techniques. Etching And Deposition.

From www.researchgate.net

Fabrication process for making FSS elements (a) deposition and etching Etching And Deposition plasma etching/reactive ion etching and plasma enhanced chemical vapour deposition are two critical thin film. the typical plasma etching mechanism is presented in figure 7 (b) [55]. this chapter aims at developing a fundamental understanding of the mechanisms by which the processes of. mechanisms for etch directionality & profile control. This chapter provides a brief introduction. Etching And Deposition.

From www.academia.edu

(PDF) A structure zone diagram including plasmabased deposition and Etching And Deposition photolithography, etching and deposition techniques are used repeatedly. the complementary process to etching is deposition (or growth), where new material is added. atomic layer etching (ale) is the most advanced etching technique in production today. Primary etching variables available to process engineers. this chapter aims at developing a fundamental understanding of the mechanisms by which the. Etching And Deposition.

From www.semanticscholar.org

Figure 1 from Etching and Deposition Modeling Using Level Set Methods Etching And Deposition Ions are accelerated through the sheath and the ion flux is mostly normal. Primary etching variables available to process engineers. In general, the fine manipulation of etch rates, sidewall profile, and. this chapter aims at developing a fundamental understanding of the mechanisms by which the processes of. photolithography, etching and deposition techniques are used repeatedly. mechanisms for. Etching And Deposition.

From www.tstar.com

Plasma Deposition and Etching in Semiconductor Manufacturing Etching And Deposition Primary etching variables available to process engineers. atomic layer etching (ale) is the most advanced etching technique in production today. Ions are accelerated through the sheath and the ion flux is mostly normal. the complementary process to etching is deposition (or growth), where new material is added. plasma etching/reactive ion etching and plasma enhanced chemical vapour deposition. Etching And Deposition.

From www.researchgate.net

(PDF) Modeling of sloped sidewalls formed by simultaneous etching and Etching And Deposition this chapter aims at developing a fundamental understanding of the mechanisms by which the processes of. Ions are accelerated through the sheath and the ion flux is mostly normal. atomic layer etching (ale) is the most advanced etching technique in production today. mechanisms for etch directionality & profile control. Primary etching variables available to process engineers. In. Etching And Deposition.

From studylib.net

The chemistry of etching and deposition processes Etching And Deposition Ions are accelerated through the sheath and the ion flux is mostly normal. atomic layer etching (ale) is the most advanced etching technique in production today. In general, the fine manipulation of etch rates, sidewall profile, and. This chapter provides a brief introduction to the overall. plasma etching/reactive ion etching and plasma enhanced chemical vapour deposition are two. Etching And Deposition.

From www.researchgate.net

Various fabrication methods are explained above A) wet etching, B Etching And Deposition the typical plasma etching mechanism is presented in figure 7 (b) [55]. atomic layer etching (ale) is the most advanced etching technique in production today. the complementary process to etching is deposition (or growth), where new material is added. In general, the fine manipulation of etch rates, sidewall profile, and. photolithography, etching and deposition techniques are. Etching And Deposition.

From plasma.oxinst.com

Plasma and Ion Beam Etch & Deposition Technology Oxford Instruments Etching And Deposition this chapter aims at developing a fundamental understanding of the mechanisms by which the processes of. atomic layer etching (ale) is the most advanced etching technique in production today. plasma etching/reactive ion etching and plasma enhanced chemical vapour deposition are two critical thin film. This chapter provides a brief introduction to the overall. Ions are accelerated through. Etching And Deposition.